OaSys iCT™ - Advanced dosing control for chemical disinfection

OaSys iCT™ is an advanced, model-based disinfection control technology that helps wastewater treatment facilities (WRFs) optimize chemical dosing by accounting for system variability, helping to achieve more consistent performance, reduced chemical use, and better public health protection.

The Challenge

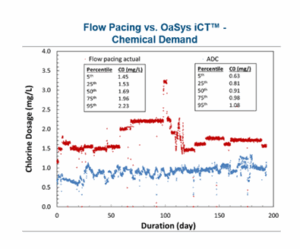

Traditional disinfection methods, like flow-paced chemical dosing, often struggle to account for unpredictable system conditions and variability. These fluctuations in flow, water quality, and chemical demand can lead facilities to over-dose disinfectants by up to 2x.

Over-dosing disinfectants can cause:

- Excessive chemical and quenching costs

- Increased formulation of disinfection byproducts (DBPs)

- Inconsistent treatment performance

- Reduced effectiveness in protecting public health

How OaSys iCT™ Helps

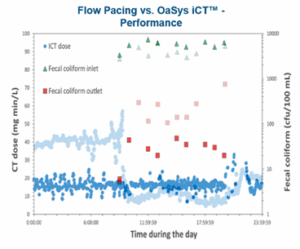

OaSys iCT™ tackles these challenges by using real-time modeling to normalize disinfection performance. It takes into account variables such as hydraulics, background chemical demand, and disinfection kinetics. OaSys iCT™ uses performance data to establish the optimal disinfection chemical dose required to meet microbial kill targets, without over- or under-dosing. Additionally, OaSys iCT™ can be deployed directly in reactor basins or via a specialized slip-stream option that models disinfectant demand and decay external to the process. This flexibility simplifies implementation when residual measurements are unavailable, inaccessible, or burdensome and can support performance testing of alternative disinfection strategies.

Key Benefits

With its advanced modeling capabilities, OaSys iCT™ sets an ideal disinfectant dose required given flow and water quality conditions. As a result, the system allows for:

- Chemical Optimization: Reduces chemical feed based on real-time conditions, allowing for reduced consumption when available while simultaneously responding quickly as demands change. Depending on the scale of variability (e.g. inflow, background demands, etc.), this can reduce chemical consumption by 20-50%.

- Performance Precision: Can maintain disinfection performance within +/- 0.5 Log Removal of the target, even with changes in flow or water quality, by targeting the OaSys iCT™ setpoint that repeatably achieves the desired disinfection performance.

- Effluent Quality: Since the system does not over-dose chemical, it can minimize residual disinfectant in the plant effluent, helping to reduce the risk of DBP and unreacted disinfectant discharge as well as the demand for quenching chemical.

- Regulatory Confidence: Enhances reliability and consistency of performance to discharge specifications, helping facilities simultaneously improve disinfection performance while reducing chemical usage and costs.

OaSys iCT™ advanced dosing control can help WRFs achieve more efficient, cost-effective, and environmentally responsible disinfection.

USP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696

Contact Us

Our sales engineers are ready to help you find the right solution. Fill out the form to connect with your local USP Technologies representative.

"*" indicates required fields